OPTIONS

The plant can be equipped with the following options in order optimise the production and to meet the final quality required.

Considering the glasses features and the different needs it is possible to combine the options to obtain the better possible result.

CONVECTIVE AIR HEATING SYSTEM

In the heating chamber it is installed an additional air heating system, upper and/or lower, in order to promote the convective heat exchange.

With this system it is possible to produce low-e glasses up to E = 0,01, to improve the production of tinted, printed, enameled and similar glasses, and to improve the normal glass quality and production.

PRE BENDING ROLLS

For deep bending productions.

CONTINUOUS RING SYSTEM

Whit this option is possible to use a lower (female) mould whit continuous boundary ring: the rolls are completely internal to the ring and in this way is possible to avoid the slots in the female ring for the rolls passage.

SHUTTLE SYSTEM

After the press cycle a special shuttle takes over the formed glass to transfer them to the tempering section: in this way there is no contact between hot glass and rolls before the tempering cycle is completed.

In the cooling section it is included an automatic unloading system.

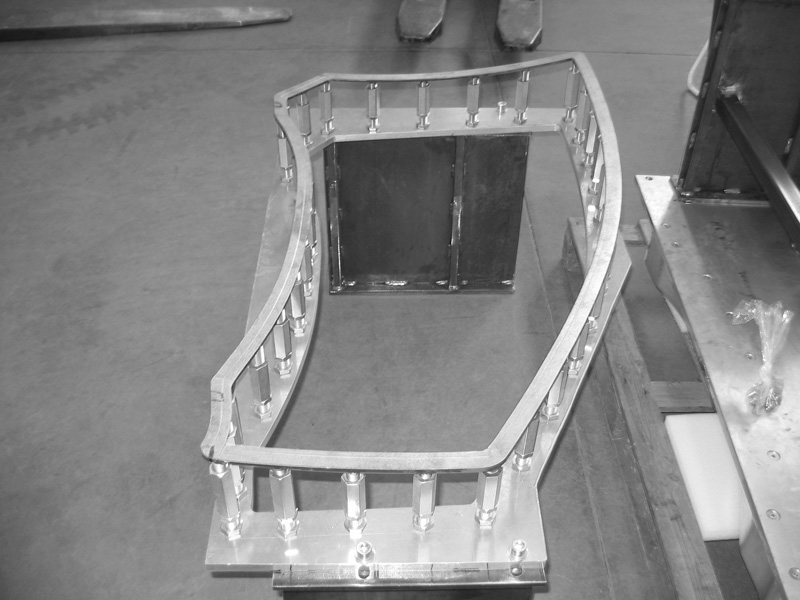

VACUUM SYSTEM

With this option it is possible to shape the glass by the complete adhesion of the hot glass to the male mould.

A vacuum system is connected to the male mould surface: a number of little holes assure an homogeneous distribution of the suction on all the surface; the glass is sucked up and take the exact required shape.

The “normal vacuum mould” is composed of a vacuum chamber closed by an aluminium plate with the glass shape.

The “3D vacuum mould”, for higher production quality, is realized from a single aluminium block, manufactured by a 3D machine.

HEATED MALE MOULD SYSTEM

With this option is possible to heat the 3D vacuum male mould to avoid the glasses loss temperature during the press cycle and to obtain a better glass quality.

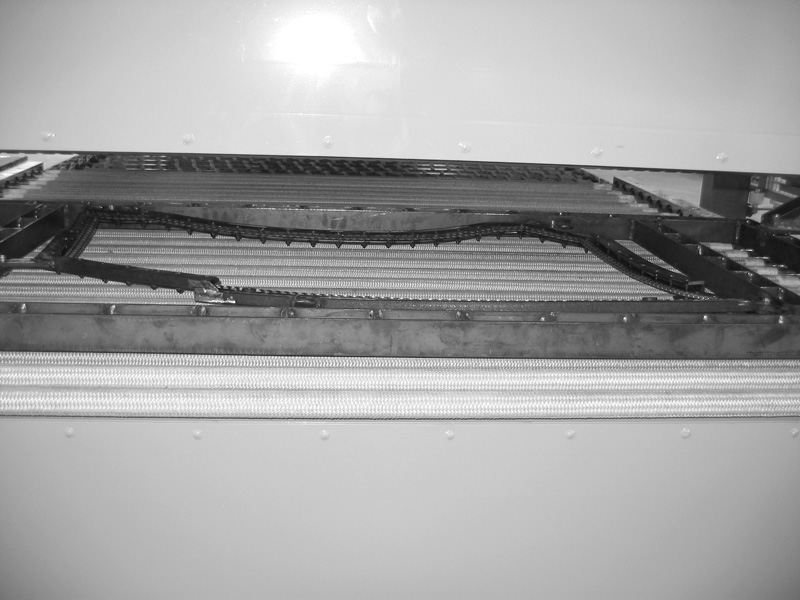

SHAPED BLOWING BOXES

To produce glasses with beep bending in the perpendicular direction of the glass flow, as backlights, it is possible to utilise in the tempering section “shaped” blowing boxes, interchangeable for each family of profiles.

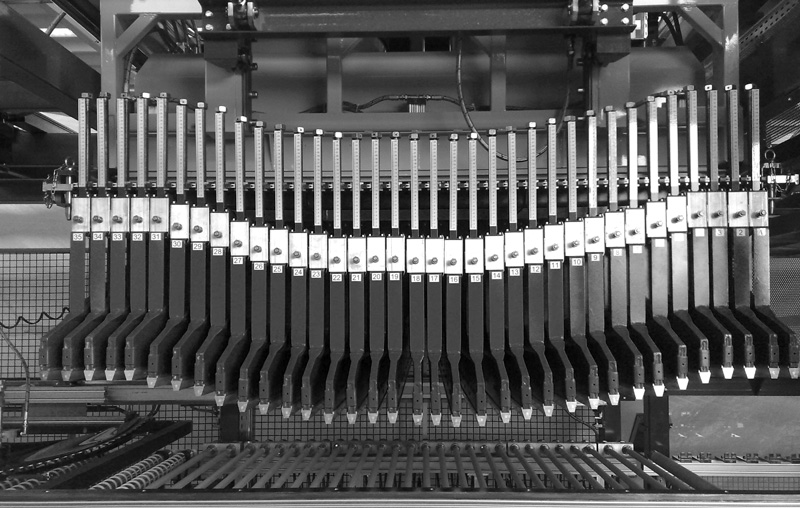

SHAPED BLADES

To produce glasses with beep bending in the perpendicular direction of the glass flow, as backlights, it is possible to utilise in the tempering section “shaped” blades, interchangeable for each family of profiles.

ADJUSTABLE BLOWING BOXES

To produce glasses with deep bending in the direction of the glass flow, the blowing boxes are conformable and can be adapted to the particular shape of the glass to be processed. During any tempering cycle the blowing boxes are moved vertically to get as close as possible to the glass surface.

MOVING BLOWING BOXES

To produce spherical glasses, high double curvatures, glasses with deep bending. During any tempering cycle the shaped blowing boxes are moved vertically to get as close as possible to the glass surface.

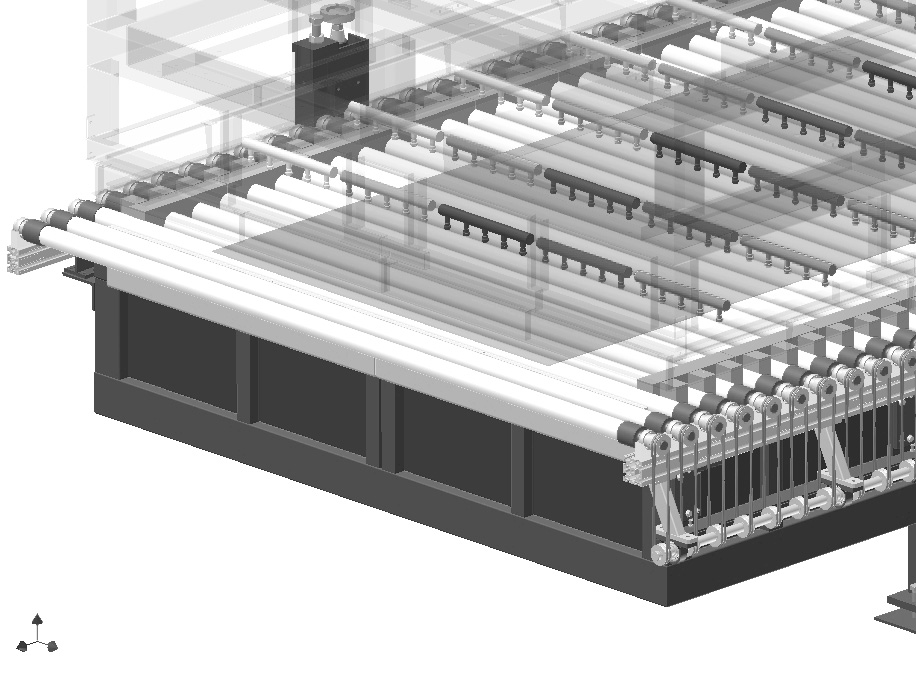

FLAT CONVEYOR

In the bending plants, it is possible to replace the press section with a special insulated conveyor for flat production: the conveyor avoids the glasses loss temperature before the glasses arrival in the tempering section increasing the glass quality. In the same time it allow to change outline of the press moulds for the next bent glass production, without loss of furnace production time.