OTHER PROJECTS

Thanks to its experience in design and automation, BHT is able to supply plants on specific customer request for special applications both in the field of glass and in other areas.

Some examples of realizations are:

FURNACE FOR LARGE GLASS BENDING

Static oven for glass bending up to 10,000 x 3,400 x H1,400 mm..

EXPERIMENTAL FURNACE FOR MICROWAVE GLASS HEATING

R&D project: innovative plant for glass treatment with microwave heating system.

TEST FURNACE FOR PAINT DRYING

Laboratory plant to test new paints and compounds on automotive glass tempering.

COILER MACHINE

Machine for coils fully automatic: wrapping of cable or pipe according to diameter, length, number of turns, coil diameter and with final packaging of the coil.

TERMOMARKER MACHINE

Machine for hot stamping on rubber transmission belts and similar.

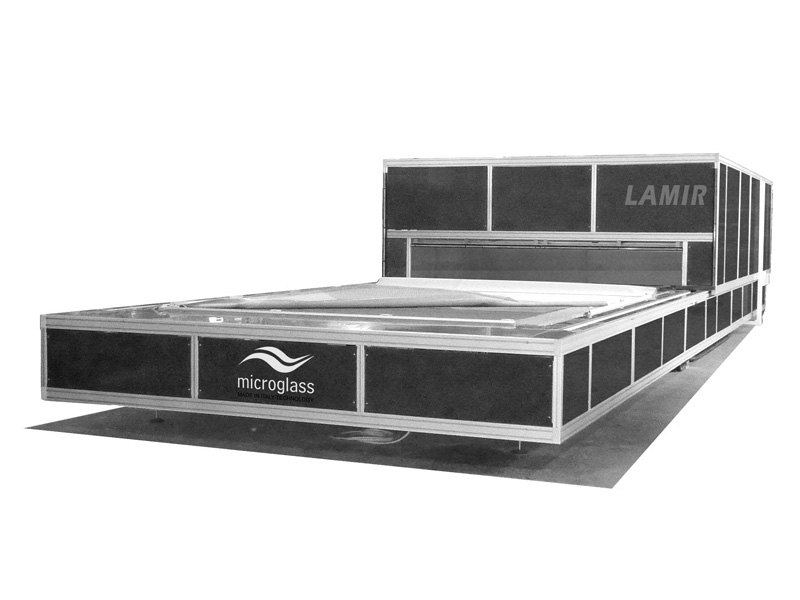

BHT also collaborates with MICROGLASS Company (http://microglass.biz/en) for the supply of a wide range of machines and equipments for glass processing, such as:

– LAMINATION INFRARED OVENS

Series FLY, JET, JUMBO with different dimensions, single or double drawer; for flat and/or curved glass.

– REFRIGERATED BOX FOR EVA/PVB

– MICROWAVE CONTINUOUS OVENS FOR PAINT DRYING

Continuous ovens for paint drying that combine microwave, infrared, hot air: thanks to the unique MW technology these systems are able to provide performance and characteristics on the final products over any other system on the market.

– MICROWAVE CABINS FOR PAINT DRYING

Cabins for paint drying that combine microwave, infrared, hot air: similar to the continuous ovens, for static treatments and batch productions.

– UV OVENS

UV ovens energy saving and high performances thanks to the innovative UV FULL DIGITAL IGNITERS and to the particular construction and processing features.

– UV FULL DIGITAL IGNITERS

Full Digital devices for UV lamp ignition, energy savings and high performances; range available for all powers.

Website: http://microglass.biz/en/products.